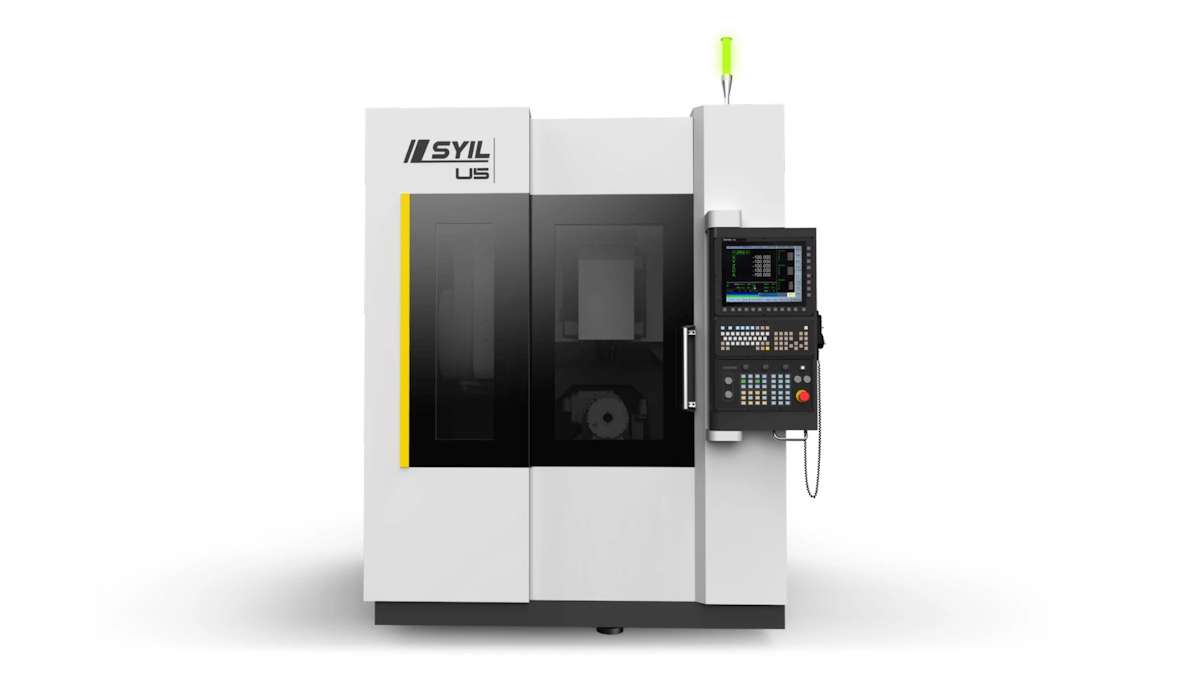

New SYIL U5 Trunion CNC Machining Centre 5-Axis (13296)

Syntec 22MA, HSK-E40, Ø200, 11kW, 30,000rpm

Availability: Ex-import

Price: POA

A 5-Axis CNC Mill With a Very Attractive Quality-To-Price Ratio

Less installation space and the highest efficiency: U5 is the most compact machining center in SYIL's U series of five-axis machines. It is specifically designed for processing cubic workpieces weighing up to 100 kg.

The machine has a compact structure, powerful performance, stable and reliable operation, high dynamic performance, and can be quickly installed and easily operated and maintained.

Experience Precision and Power in a Compact Size:

Optimized floor space (Only 3.20 m²)

·Achieve optimal integration with machine width of <1.80 m

·Mineral casting bed structure

·Built-in Heidenhain encoder

·Direct drive servo system and high precision guide rail

Rotating area b-axis rotatable -35° / +110°

·5-axis machining capability, complete processing of complex workpieces

·Equipped with a standard 32-bit tool magazine, with a quick tool change time of less than 2.0s

·High dynamic performance electric spindle with 30,000 RPM speed, 11 KW power, and Cts high-pressure center water outlet support

·Expandable real-time thermal compensation function

Features:

The SYIL U5 is a state-of-the-art 5-axis CNC mill that offers a wide range of features and benefits for industrial machinists. Here are some of the key features of this versatile machine:

·5-axis Capability: The U5 provides simultaneous 5-axis machining, allowing for complex and precise operations. This capability enables machinists to create intricate and multi-sided parts with ease.

·Versatile Machining Options: With a spacious work envelope of 500 x 400 x 250 mm, the U5 can accommodate a wide range of part sizes and shapes. It also offers a full 360-degree rotation on the A-axis and a 150-degree rotation on the B-axis, providing maximum flexibility for machining complex geometries.

·High-Speed Machining: Equipped with a high-speed spindle of up to 30,000 RPM, the U5 ensures fast and efficient cutting. This feature reduces machining time and increases productivity, making it ideal for high-volume production.

·Tool Changer: The U5 comes with a 32-tool capacity carousel-style automatic tool changer. This allows for quick and seamless tool changes, minimizing downtime and optimizing efficiency.

·Advanced Control System: The Syntec Control software is user-friendly and intuitive, making it easy for machinists to program and operate the U5.

Specifications:

Table

Plate diameter: 200mm

Maximum machining diameter: 250mm

Swiveling range: +/-100°

T-slots: 4/12 H7

Maximum table load (0°): 60kg

Maximum table load (90°): 40kg

Travel

X Travel: 500mm

Y Travel: 300mm

Z Travel: 250mm

Distance between spindle end and rotary table top: 50-300mm

Distance between spindle and column surface: 305mm

Spindle

Spindle Nose: HSK-E40

Spindle Speeds: 30,000rpm

Feed

XYZ Rapid Traverse: 30,000mm/min

XYZ Cutting Feed: 10,000mm/min

B Rapid Traverse: 10,800 deg/min

C Rapid Traverse: 18,000 deg/min

BC Cutting Feed: 3,600 deg/min

Auto Tool Changer

Tool Type: Arm Type

Tool Holder: HSK-E40

Tool Storage Capacity: 32 pcs

Maximum Tool Length: 200mm

Maximum Tool Weight: 2kg

Maximum Tool Diameter: 20mm

Tool to Tool: 1.5s

Power

Spindle motor output (Rate/Max): 5.5/7.5kW

Drive motors (X, Y, Z): 1.7/1.7/2.4kW

Power source: AC380V/3-Phase

Power: 12kVA

By default, the SYIL U5 includes:

SCHNEEBERGER high-quality mineral casting frame

SCHNEEBERGER high-precision ballscrew and linear guide

30,000 RPM HSK E40 Spindle

32 Units ATC umbrella type

SYIL 220MA 15" screen CNC Controller with 5 Axis Servo Motors

Heidenhain optical scale for 3 axis

200mm 5-Axis rotary table DDR type

Machine Size and Weight

Height: 2400mm

Floor Size (LxW): 1950x2050mm

Net Weight: 5000kg

Gross Weight: 5200kg

Options:

Probe System | Wireless type | Marposs

Tool Setter laser type | Marposs

Filtermist

Central Coolant System(CTS 20 Bar)

Chip Conveyor

SYIL Tooling Package

- Commissioning, hydraulic oil and transportation for new and used machine(s) are for the buyers account unless otherwise specified in writing by TH MACHINE TOOLS CC.

- All goods must be paid in full before collection or delivery, unless otherwise specified in writing by TH MACHINE TOOLS CC, who reserves the right to charge interest on all overdue amounts.

- All goods remain the property of TH MACHINE TOOLS CC until paid in full.

- ALL DELIVERIES are at the cost of the buyer.

- ALL DELIVERIES exclude foundation preparation, anchoring and electrical connection unless otherwise specified in writing by TH MACHINE TOOLS CC.

- GOODS DELIVERED remain the property of TH MACHINE TOOLS CC until fully paid for and we retain the right to repossess and remove any goods supplied at our own discretion, holding the buyer liable for any additional costs deriving directly from such removal and or damages inflicted to the goods while such goods were used by the buyer.

- GOODS TRANSPORTED in any other way than our own transport are in transit at the buyer’s risk which hereby does indemnify and hold us blameless against any claim which he may have in respect of damages or any other cause whatsoever.

- One day machine operational training is included with all new CNC / NC machine purchases plus an extra two days application training with new HURCO machine purchases. Additional training is available at the cost of the buyer.

- A warranty is offered on all new machines from date of collection / delivery against faulty material and/or workmanship excluding electrical components and hydraulic seals.

- Industrial machines: Twelve (12) months warranty.

- Light-duty machines: Six (6) months warranty.

-

The warranty will be invalidated under the following conditions:

- Breakdown /malfunction caused while operating machine outside factory capacity specifications.

- Breakdown /malfunction caused by third party electrician / technician.

- Breakdown /malfunction caused by operator error.

- Breakdown /malfunction caused by fair wear and tear.

- In case of a warranty call-out the buyer will be responsible for all traveling expenses exceeding a 100 kilometer radius as well as all accommodation expenses.

- All out of warranty call-outs are charged Rand per hour + Rand per kilometer. Time begins at the point of departure and ends upon point of return.

- All used / reconditioned machines are sold “As Is”, unless otherwise specified and a Working Warranty is issued in writing by TH MACHINE TOOLS CC.

- TH MACHINE TOOLS CC does not warrant to the buyer that the tooling are fit for the purpose sold and/or are free from any defects whether latent or patent.

- TH MACHINE TOOLS CC will endeavor to pass on the benefit of any manufacturer’s guarantee but apart there from there shall be no liability whatsoever attaching to TH MACHINE TOOLS CC.

- Prices are subject to change due to currency fluctuations and/or increases imposed by our supplier.

Send us a request for quotation if you want us to deliver.

Our fleet of bakkies and rigging trucks enables us to provide a comprehensive range of delivery and rigging services.

We also work with other reputable transport companies for all long distance transport and export services.